PSA & VPSA OXYGEN GAS GENERATORS

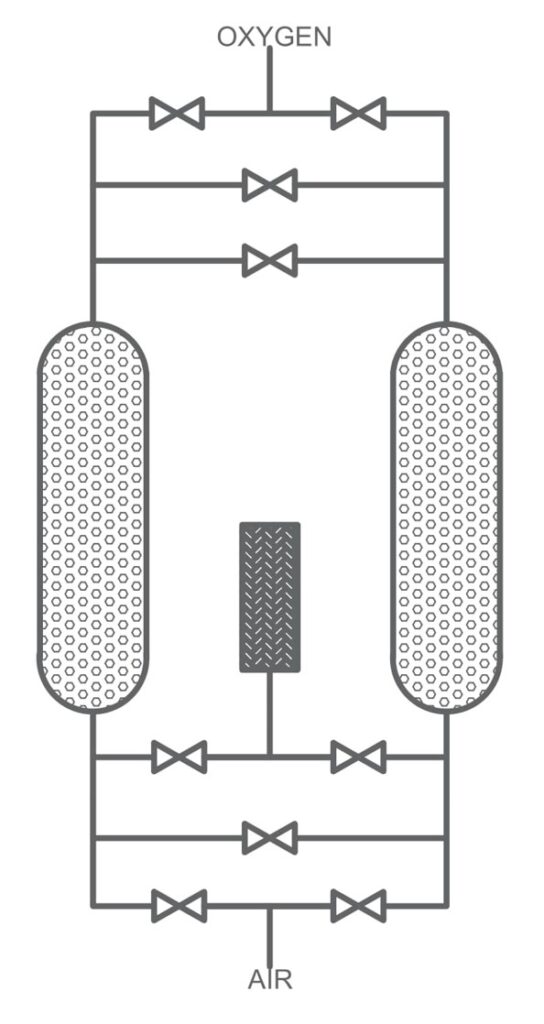

Standalone Twin Tower PSA Oxygen Gas Generator (STT Oxygen Series)

Designed to replace an existing gas generator in a facility or suitable where a customer already has excess dry compressed air available with a suitably sized air receiver & oxygen storage tanks to go with it.

Easy start-up at the site with minimal expertise.

Custom-designed to meet your process flow rate requirements and pressures up to 5 Barg or 72.5 Psig.

Suitable to generate oxygen gas purity up to 96 %.

Field Expandable Standalone PSA Oxygen Gas Generator (FES Oxygen Series)

Designed to replace an existing gas generator in a plant or suitable where a customer already has excess dry compressed air available with a suitably sized air receiver & oxygen storage tanks to go with it.

FES system grows with your operation & flow output of the system can be increased by adding additional towers in the future instead of investing again in a whole new gas generator as long as the system can be supplied with required excess dry compressed air. Allows easy expansion at the site.

Easy start-up at the site with minimal expertise.

Custom-designed to meet your process flow rate requirements and pressures up to 5 Barg or 72.5 Psig.

Suitable to generate oxygen gas purity up to 96 %.

Twin Tower VPSA Oxygen Gas Generator

VPSA oxygen gas generator is designed for large-scale applications where oxygen flowrate requirements exceed a minimum of 200 Nm3/hr or 120 Scfm.

Oxygen gas delivery pressure range 3-5 Psig.

Suitable to generate oxygen gas purity up to 93%.

Requires commissioning by a gas generation expert.

Low-Pressure Oxygen Gas Generation Skid

A low-pressure oxygen gas generation skid comes preinstalled with all main components of the system such as a Low-Pressure Air Compressor, Refrigerated or Desiccant Air Dryer, Oil & Water Separator, Air Filtration, Air Receiver Tank, STT or FES PSA Oxygen Gas Generator, Oxygen Storage Tank and Process Filtration.

A skidded system needs to be placed at the designated area & connected with your electrical supply to start producing oxygen gas onsite instantly for your process.

Allows easy start-up at the site with minimal expertise.

Custom-designed to meet your process flow rate requirements and pressure up to 5 Barg or 72.5 Psig.

Suitable to generate oxygen gas purity up to 96 %.

High-Pressure Oxygen Gas Generation Skid

A high-pressure oxygen gas generation skid comes preinstalled with all main components of the system such as a Low-Pressure Air Compressor, Refrigerated or Desiccant Air Dryer, Oil & Water Separator, Air Filtration, Air Receiver Tank, STT or FES PSA Oxygen Gas Generator, Oxygen Storage Tank, High-Pressure Oxygen Booster Compressor, High-Pressure Oxygen Storage Tank or High-Pressure Oxygen Bottles as required, and Process Filtration.

A high-pressure skidded system needs to be placed at the designated area & connected with your electrical supply to start producing high-pressure oxygen gas onsite instantly for your process.

Requires commissioning by a gas generation expert.

Custom-designed to meet your process flow rate requirements and pressures up to 345 Barg or 5000 Psig.

Suitable to generate oxygen gas purity up to 96 %.

Plant Floor Installation Suitable For Both Low & High-Pressure Oxygen Gas Generating Systems

In this configuration, a customer is supplied with all the main system components such Low-Pressure Air Compressor, Refrigerated or Desiccant Air Dryer, Oil & Water Separator, Air Filtration, Air Receiver Tank, STT or FES PSA Oxygen Gas Generator, Low-Pressure Oxygen Storage Tank, High-Pressure Oxygen Booster Compressor, High-Pressure Oxygen Storage Tank or High-Pressure Oxygen Bottles as required, and Process Filtration.

System installation takes place at the site followed by commissioning by a gas generation expert.

Custom-designed to meet your process flow rate requirements and pressures up to 345 Barg or 5000 Psig.

Suitable to generate oxygen gas purity up to 96 %.

Containerized Oxygen Gas Generating System

In this configuration, the gas generating system is housed inside a sea container with all main components such as Low-Pressure Air Compressor, Refrigerated or Desiccant Air Dryer, Oil & Water Separator, Air Filtration, Air Receiver Tank, STT or FES PSA Oxygen Gas Generator, Low-Pressure Oxygen Storage Tank, High-Pressure Oxygen Booster Compressor, High-Pressure Oxygen Storage Tank or High-Pressure Oxygen Bottles as required, and Process Filtration.

Requires commissioning by a gas generation expert.

Custom-designed to meet your process flow rate requirements and pressures up to 345 Barg or 5000 Psig.

Suitable to generate oxygen gas purity up to 96 %.

How a PSA Oxygen Gas Generator Works

Working Principle

The air that we breathe on earth is made up of 78 % nitrogen and 21 % oxygen. Air also has other inert gases in very small quantities.

The pressure swing adsorption(PSA) process is designed around two or more adsorber towers which are filled with zeolite molecular sieve(ZMS) material. An Air compressor is used to supply compressed air which is further treated with a refrigerated dryer to reduce the air dewpoint to +3 to +5 Deg C & set of filtration to make compressed air completely free of any heavy particulate & oil contaminations. Dry & oil-free air then enters the adsorber tower where zeolite molecular sieve material has a strong affinity for nitrogen & water molecules therefore these molecules get adsorbed to the ZMS porous surface under pressure and pure oxygen gas is collected & stored in a storage tank at the outlet. when one tower is under adsorption, another tower is regenerated by reducing the tower pressure close to atmospheric pressure to release the adsorbed gases and allowing a small amount of pure oxygen gas as purging gas to remove any nitrogen & water vapor impurities, the cycle repeats itself to produce oxygen gas continuously.

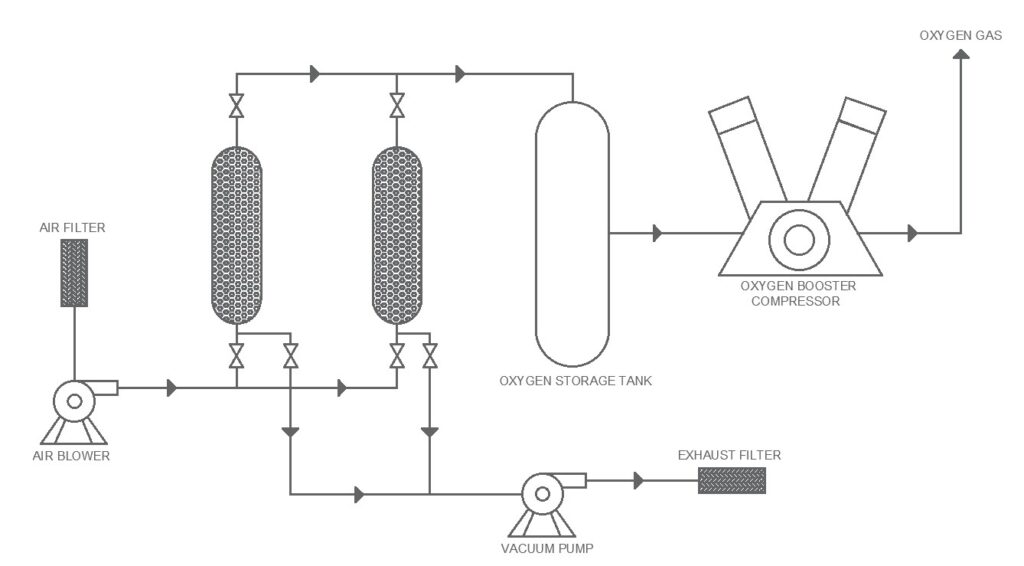

How a VPSA Oxygen Gas Generator Works

Working Principle

In a VPSA oxygen gas generator, the air is supplied to adsorber towers by a low-pressure blower instead of an air compressor. separation of oxygen from the tower takes place exactly as in a standard PSA system with the exception that the towers are regenerated by applying the vacuum to zeolite molecular sieve material.

Industrial Applications

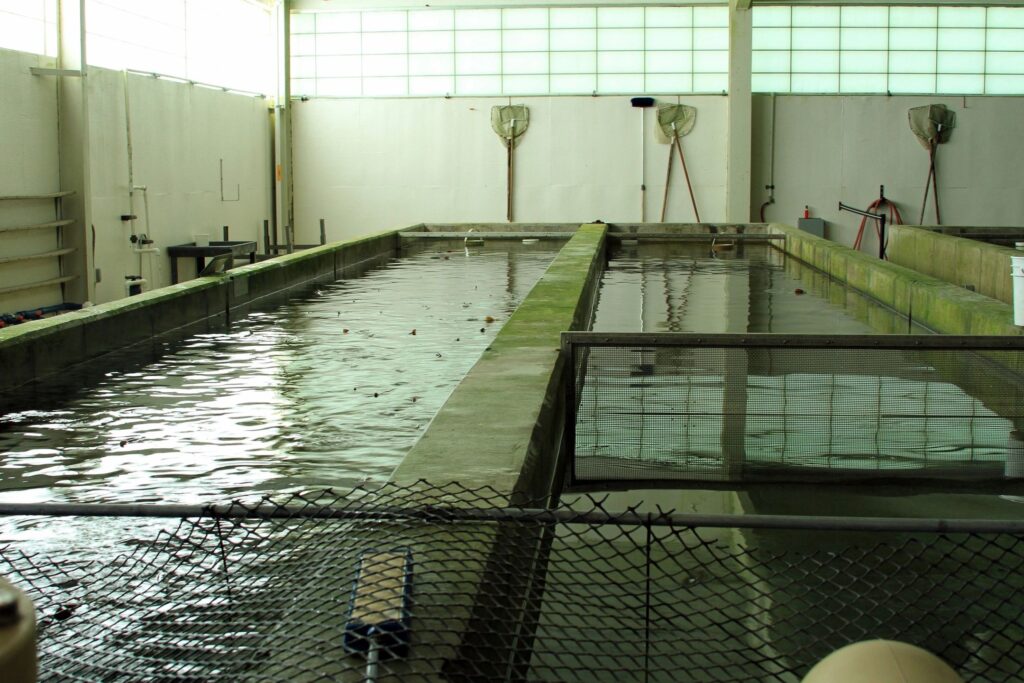

Fish Farming & Aquaculture

Oxygen Gas Purity Required: 90 % or better

Hospitals

Oxygen Gas Purity Required: 93 %

Waste Water Treatment

Oxygen Gas Purity Required: 90 % or better

Hatcheries

Oxygen Gas Purity Required: 90 % or better

Gold Mining

Oxygen Gas Purity Required: 93 % +/- 3 %

Paper Mill

Oxygen Gas Purity Required: 90 % or better

Horticulture

Oxygen Gas Purity Required 90 % or better

Agriculture

Oxygen Gas Purity Required 90 % or better

Email or Call an Expert

Phone

+1 (647) 534-8539

Enquire Now

Certifications

Our on-site gas generating systems are designed and manufactured in compliance with North American standards.