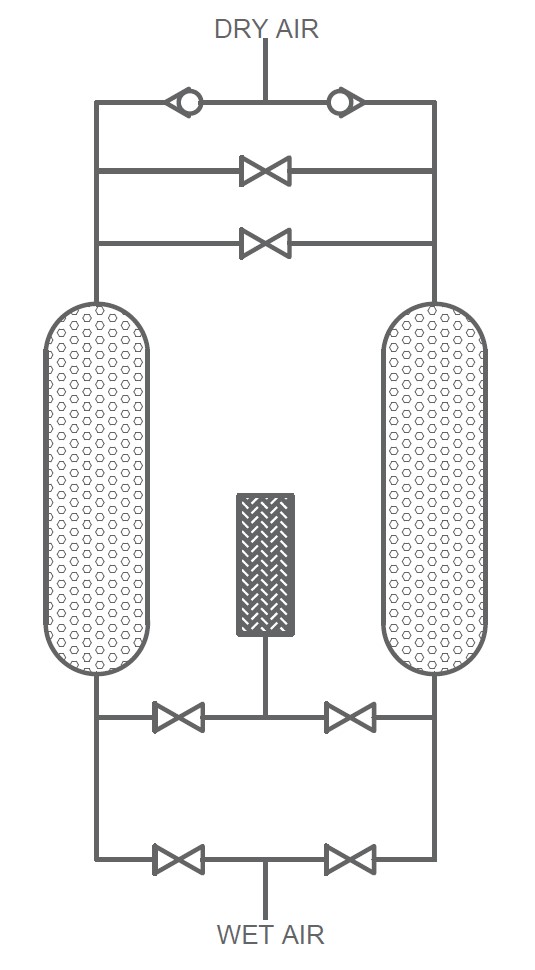

TWIN TOWER HEATLESS DESICCANT AIR DRYER

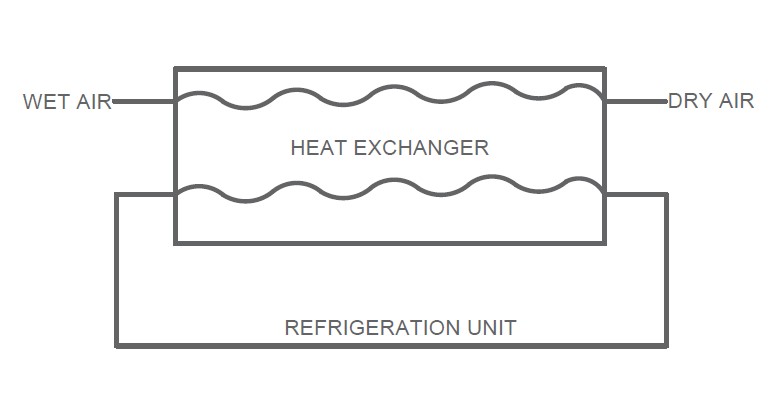

REFRIGERATED AIR DRYER

In compressed air systems, moisture can pose a significant challenge, leading to equipment damage, decreased efficiency, and compromised product quality. To address this issue, air dryers are utilized to remove moisture from compressed air, ensuring clean, dry air for various industrial applications. Two common types of air dryers are refrigerated dryers and desiccant dryers, each offering unique advantages and suitability for different dewpoint requirements.

Understanding Dewpoint:

Dewpoint is a crucial concept in understanding humidity and its impact on air quality and equipment performance. It refers to the temperature at which air becomes saturated with moisture, leading to condensation or dew formation. In simpler terms, it’s the temperature at which the air can no longer hold all the moisture it contains, causing water vapor to condense into liquid water. Dewpoint is a critical factor in compressed air systems because it indicates the moisture content in the air. Lower dewpoints signify drier air, which is essential for preventing corrosion, contamination, and damage to pneumatic equipment. Understanding dewpoint is essential for selecting the appropriate air dryer to achieve the desired level of dryness for specific applications.

Refrigerated Compressed Air dryers:

Refrigerated dryers operate on the principle of cooling compressed air to lower its temperature, causing moisture to condense and separate from the air stream. The condensed moisture is then drained from the system, leaving behind dry, low dewpoint compressed air. Refrigerated dryers are suitable for applications with moderate dewpoint requirements, typically ranging from 37.4°F to 41°F (3°C to 5°C).

Advantages of refrigerated dryers include:

Cost-effectiveness: Refrigerated dryers are generally more affordable to purchase and operate compared to desiccant dryers.

Energy Efficiency: They require less energy consumption, especially in moderate temperature environments.

Simple Operation and Maintenance: Refrigerated dryers have fewer moving parts and require minimal maintenance, resulting in lower lifecycle costs.

Desiccant Compressed Air Dryers:

Desiccant dryers employ adsorption process to remove moisture from compressed air, utilizing materials such as molecular sieve or activated alumina to attract and retain moisture molecules. These dryers are capable of achieving extremely low dewpoints, making them suitable for applications requiring critical air quality, such as pharmaceuticals, electronics manufacturing, and food processing.

Advantages of desiccant dryers include:

Low Dewpoint Capability: Desiccant dryers can achieve dewpoints as low as -40°F (-40°C) or lower, ensuring the highest level of air purity for sensitive applications.

Versatility: They can operate effectively in a wide range of environmental conditions, including high humidity and low temperatures.

Regenerative Capability: Desiccant dryers can be equipped with regenerative features, allowing for the regeneration of desiccant materials to extend their lifespan and maintain performance.

Steps to Choose the Right Dryer based on Dewpoint Requirement:

- Determine Dewpoint Requirement: Identify the specific dewpoint requirement for your application based on equipment specifications, industry standards, and process considerations.

- Assess Operating Conditions: Consider environmental factors such as ambient temperature, humidity levels, and variations in air demand to determine the optimal dryer type for your compressed air system.

- Evaluate Air Quality Standards: Determine if your application requires standard air quality (ISO 8573) or if it necessitates higher purity levels, such as for critical processes or sensitive products.

- Calculate Air Demand: Estimate the compressed air demand of your system to ensure that the selected dryer can meet the required flow rate and moisture removal capacity.

- Consider Lifecycle Costs: Compare the initial investment, energy consumption, maintenance requirements, and expected lifespan of refrigerated and desiccant dryers to make an informed decision based on long-term cost-effectiveness.

- Consult with Experts: Seek guidance from compressed air system professionals or equipment suppliers to assess your specific needs and recommend the most suitable dryer solution for your application.

Selecting the right air dryer is essential for maintaining the quality, reliability, and efficiency of compressed air systems in various industrial settings. By understanding the differences between refrigerated and desiccant dryers and following the outlined steps to choose based on dewpoint requirements, businesses can ensure optimal performance and longevity of their compressed air systems, ultimately contributing to improved productivity and product quality.

Enquire Now