Biogas, a renewable energy source derived from organic materials, plays a significant role in sustainable energy production. Its generation relies on the anaerobic digestion of organic matter, facilitated by microorganisms in the absence of oxygen. However, the efficient operation of biogas plants demands careful management of various factors, including the presence of oxygen. Contrary to the anaerobic conditions necessary for biogas production, controlled oxygen gas introduction can enhance the process by promoting microbial activity, reducing odors, and improving overall efficiency.

Enhancing Microbial Activity & Optimizing Biogas Production:

introducing controlled amounts of oxygen into the biogas digester can stimulate microbial growth and activity. This oxygen supplementation encourages the proliferation of aerobic bacteria, which synergistically work with anaerobic microorganisms to break down complex organic matter more efficiently.

The controlled introduction of oxygen gas into biogas digesters can significantly improve biogas production rates and quality. By enhancing the breakdown of organic substrates, oxygen supplementation helps maximize methane(CH4) yields while reducing the retention time required for digestion. This optimization not only boosts the overall energy output of biogas plants but also enhances process stability and reliability.

Biogas Production & On-Site Oxygen Gas Generation:

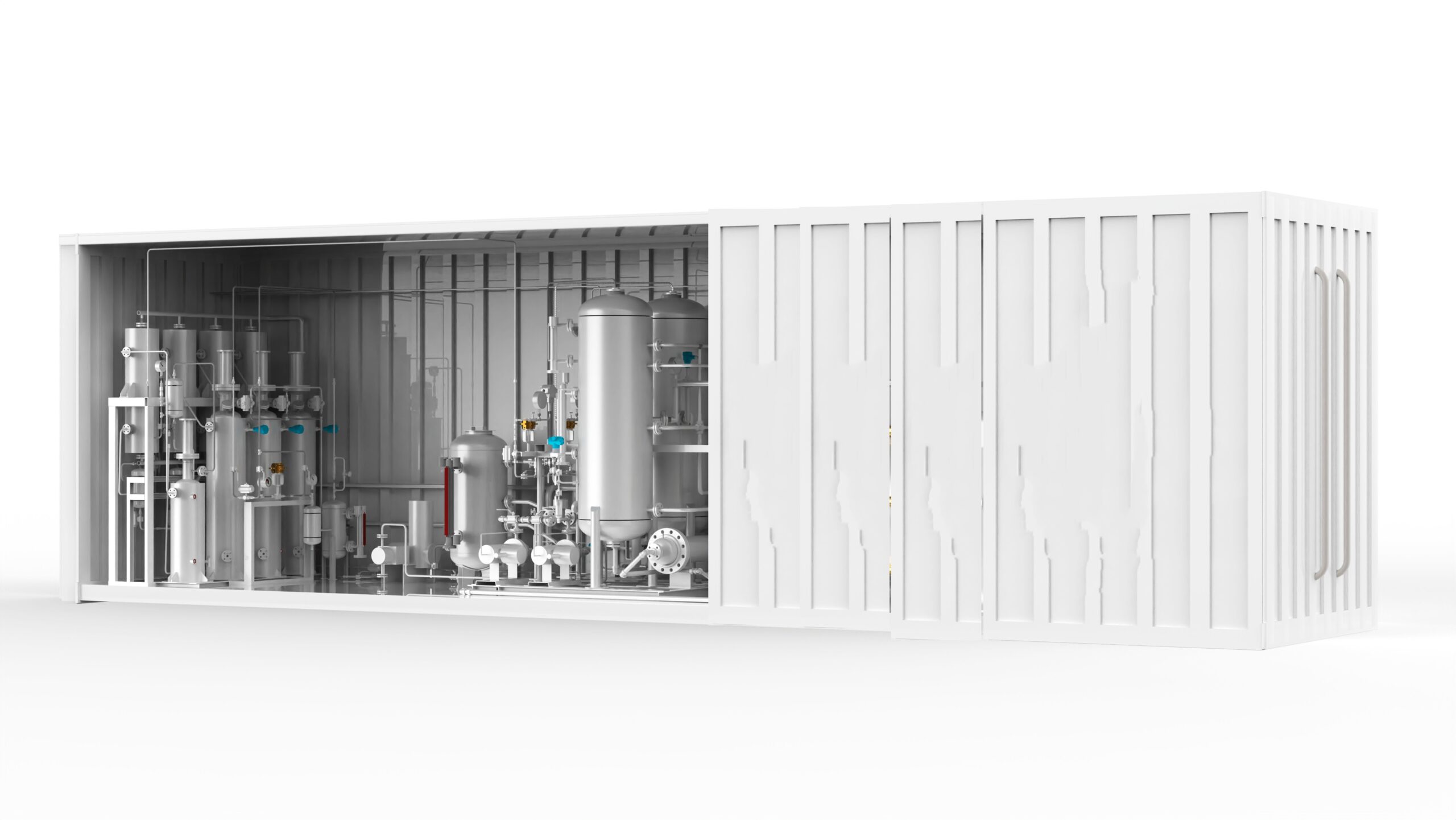

CONTAINERIZED OXYGEN SYSTEM FOR BIOGAS PRODUCTION

On-site oxygen gas generation is revolutionizing biogas generation by offering a sustainable and cost-effective solution to enhance the efficiency, reliability, and environmental performance of biogas plants. Traditionally, oxygen supplementation in biogas plants has been achieved through the purchase and delivery of compressed or liquid oxygen from external suppliers. However, this approach presents logistical challenges, transportation costs, and environmental concerns associated with the production and distribution of oxygen. On-site oxygen gas generation systems has transformed the landscape of biogas production by providing a decentralized and self-sufficient method for supplying oxygen directly at the point of use. These systems utilize advanced technologies, such as pressure swing adsorption to extract oxygen from the surrounding air and concentrate it to purity levels suitable for biogas applications.

Several ways in which on-site oxygen gas is revolutionizing biogas production:

Enhanced Process Control and Flexibility: On-site oxygen generation systems empower biogas plant operators with greater control over the oxygenation process. By producing oxygen on demand, operators can precisely adjust oxygen levels in the biogas digester according to fluctuating feedstock compositions, temperature variations, and microbial activity. This flexibility optimizes biogas production rates and quality while minimizing the risk of process upsets and downtime.

Cost Savings and Operational Efficiency: On-site oxygen generation eliminates the need for external oxygen suppliers, transportation logistics, and storage infrastructure, resulting in significant cost savings for biogas plant operators. Moreover, by reducing reliance on fossil fuel-based oxygen production methods, such as cryogenic distillation, on-site generation contributes to the overall sustainability of biogas production and mitigates carbon emissions associated with transportation and industrial processes.

Improved Reliability and Resilience: On-site oxygen generation systems enhance the reliability and resilience of biogas plants by reducing dependency on external suppliers and mitigating supply chain disruptions. By ensuring a continuous and uninterrupted supply of oxygen, even in remote or off-grid locations, these systems enhance the operational stability and performance of biogas facilities. This reliability is particularly crucial for industries reliant on continuous biogas production, such as wastewater treatment plants, agricultural facilities, and food processing facilities.

Scalability and Customization: On-site oxygen generation systems offer scalability and customization options to accommodate the specific needs and requirements of biogas plants of varying sizes and capacities. Whether it’s a small-scale anaerobic digester or a large industrial biogas facility, on-site generation systems can be tailored to deliver the precise oxygen volumes and concentrations needed to optimize biogas production while minimizing capital investment and operating costs.

Enquire Now