Wastewater treatment is a critical process in maintaining environmental sustainability and public health. One key component of effective wastewater treatment is the use of oxygen gas. Oxygen gas plays an important role in facilitating the breakdown of organic matter, removing pollutants, and ensuring the purification of wastewater before it is released back into the environment. By harnessing the power of oxygen gas, wastewater treatment plants can achieve their objectives of protecting public health, safeguarding the environment, and promoting sustainable water management practices.

AERATION:

Aeration is a fundamental step in wastewater treatment where oxygen gas is introduced into the wastewater. This is typically done through mechanical aeration systems such as diffusers, aerators, or cascading water. The introduction of oxygen promotes aerobic microbial activity, facilitating the breakdown of organic pollutants present in the wastewater. As microorganisms consume organic matter, they metabolize it into simpler, less harmful substances, effectively treating the wastewater.

aCTIVATED SLUDGE PROCESS:

The activated sludge process is a widely used method in wastewater treatment plants that relies on the addition of oxygen gas. In this process, wastewater is mixed with a culture of microorganisms (activated sludge) in an aerated tank. The microorganisms utilize the oxygen to metabolize organic pollutants present in the wastewater, thereby reducing its pollutant load. The oxygen-rich environment promotes the growth and activity of beneficial bacteria, resulting in the decomposition of organic matter and the removal of nutrients such as nitrogen and phosphorus.

OXIDATION:

Oxygen gas is also utilized in wastewater treatment for oxidation purposes. Oxidation involves the chemical reaction between oxygen and various pollutants present in the wastewater, converting them into less harmful or inert substances. For example, oxygen can be used to oxidize ammonia to nitrate in a process known as nitrification, which helps in the removal of nitrogen from wastewater. Similarly, oxygen can aid in the oxidation of sulfides to sulfates, reducing the odor and toxicity associated with hydrogen sulfide in wastewater.

ODOR CONTROL:

In addition to its role in wastewater treatment processes, oxygen gas is also employed for odor control in wastewater treatment plants. Odor issues often arise due to the presence of sulfur compounds and other volatile organic compounds in wastewater. Introducing oxygen helps in promoting aerobic conditions, which inhibit the growth of odor-producing anaerobic bacteria and facilitate the degradation of odorous compounds. By maintaining proper aeration levels, wastewater treatment plants can effectively mitigate odor concerns, ensuring a more pleasant working environment and reducing nuisance for surrounding communities.

Energy Efficiency & Sustainability:

The use of oxygen gas in wastewater treatment offers several benefits in terms of energy efficiency and sustainability. Mechanical aeration systems can be designed to optimize oxygen transfer efficiency, minimizing energy consumption and operational costs. Additionally, by promoting aerobic processes, oxygenation reduces the generation of sludge and the associated costs of sludge handling and disposal. Furthermore, efficient wastewater treatment helps in preserving water quality and safeguarding ecosystems, contributing to overall environmental sustainability.

Improving Wastewater Treatment Efficiency with Onsite Oxygen Gas Generation:

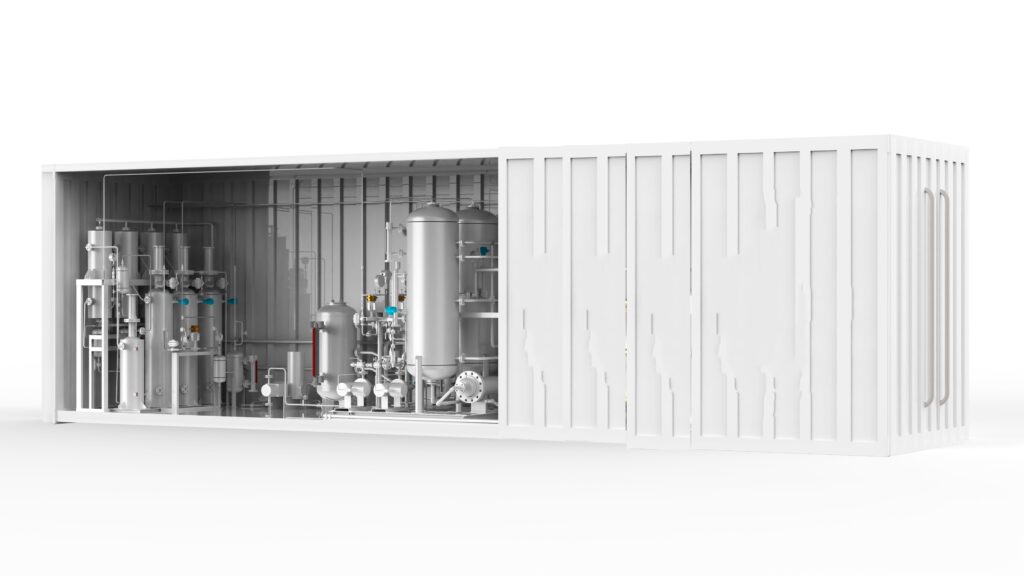

MOBILE CONTAINERIZED ON-SITE OXYGEN GAS GENERATING SYSTEM

STATIONARY ON-SITE OXYGEN GAS GENERATING SYSTEM

Onsite oxygen gas generators offer a myriad of benefits for wastewater treatment processes. By producing oxygen directly at the treatment facility, these generators eliminate the need for reliance on external sources, such as oxygen cylinders or liquid oxygen tanks, thereby reducing transportation costs and logistical complexities. Moreover, onsite oxygen generation provides a continuous and reliable supply of oxygen, ensuring uninterrupted operation of aeration systems and other oxygen-dependent processes in wastewater treatment plants. This not only enhances operational efficiency but also allows for better control over oxygen levels, leading to optimized treatment performance and improved water quality. Additionally, onsite oxygen gas generators contribute to sustainability efforts by reducing energy consumption associated with oxygen production and transportation, thereby minimizing the carbon footprint of wastewater treatment operations. Overall, the integration of onsite oxygen gas generators represents a cost-effective, reliable, and environmentally friendly solution for enhancing the effectiveness and sustainability of wastewater treatment processes.

Enquire Now