In Aviation and Automotive industries, safety and performance are paramount. Every component and every decision made can have a significant impact on efficiency, reliability, and safety. One such crucial element often overlooked is tire inflation. While air has been the traditional choice for tire inflation, nitrogen gas has emerged as a superior alternative for aircraft and automobile tires, offering numerous benefits. Moreover, the adoption of onsite nitrogen gas generators presents a compelling case for cost-efficiency and convenience. Let’s delve into the significance of nitrogen gas and the advantages of having your own onsite nitrogen gas generator.

Nitrogen gas: enhancing performance & safety

Pressure Stability: Nitrogen molecules are larger than oxygen molecules, reducing the rate at which they permeate through tire walls. This characteristic ensures more stable tire pressure over time, reducing the frequency of tire pressure checks and adjustments. Stable tire pressure is critical for maintaining optimal performance and handling, especially in aircraft where precision and stability are paramount.

Reduced Oxidation & Corrosion: Nitrogen is an inert gas, meaning it does not react with other substances. Unlike oxygen, which can cause oxidation and corrosion, nitrogen minimizes these risks. In aircraft, where tires are subjected to extreme conditions including high speeds, temperature variations, and exposure to various chemicals on runways, the reduced risk of oxidation and corrosion translates to enhanced tire longevity and safety.

Temperature Stability: Nitrogen exhibits less temperature sensitivity compared to air. This property reduces the fluctuations in tire pressure that occur due to temperature changes during flight or driving. Consistent tire pressure ensures predictable handling characteristics and minimizes the risk of blowouts, particularly critical for aircraft during takeoff and landing.

Water Vapour Reduction: Nitrogen gas is typically dry, containing minimal moisture compared to compressed air. Water vapor inside tires can lead to fluctuations in tire pressure as it expands and contracts with temperature changes. By using nitrogen, the presence of water vapor is significantly reduced, ensuring more consistent tire pressure and minimizing the risk of tire failure.

Safety: The inert nature of nitrogen reduces the risk of combustion or explosion in case of a tire failure, providing an additional layer of safety, particularly in high-risk environments such as aircraft operations.

Onsite Nitrogen Gas Generation: Cost Efficiency and Convenience

STATIONARY ON-SITE NITROGEN GAS GENERATING SYSTEM

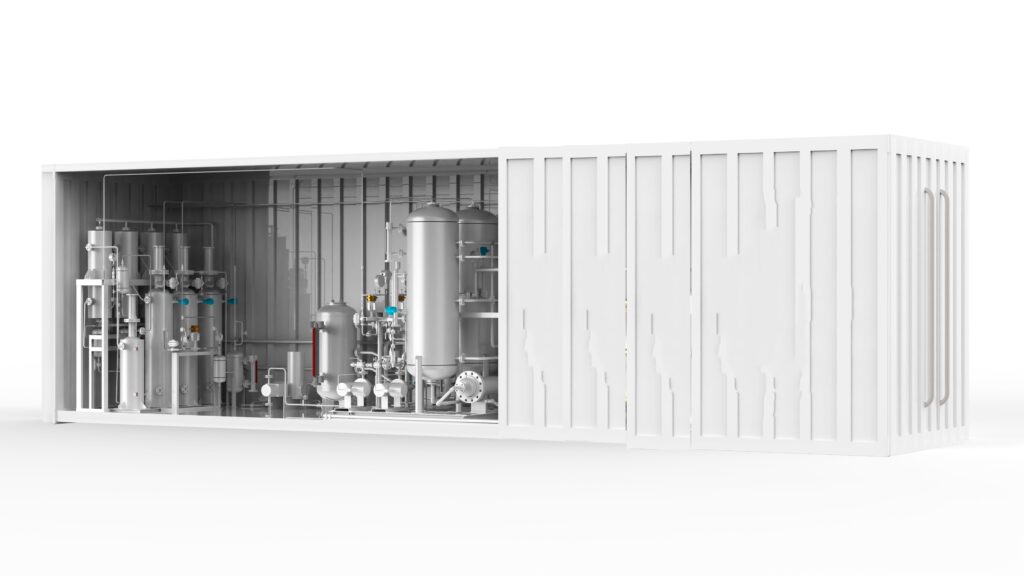

MOBILE CONTAINERIZED ON-SITE NITROGEN GAS GENERATING SYSTEM

While the benefits of nitrogen gas for tire inflation are clear, the logistics of sourcing and transporting nitrogen cylinders can be cumbersome and costly, particularly for industries with high-demand requirements like aviation and automotive. The adoption of onsite nitrogen gas generators presents an attractive solution to this challenge. These generators utilize advanced membrane or pressure swing adsorption (PSA) technology to extract nitrogen from the surrounding air, delivering a continuous and reliable source of high-purity nitrogen on-site. The advantages of onsite nitrogen gas generation include:

Cost Savings: Eliminating the need for external nitrogen supply contracts and transportation expenses results in significant cost savings over time. Onsite generation allows businesses to produce nitrogen on demand, reducing operational costs associated with downtime and logistics.

Convenience and Accessibility: Having a nitrogen generator on-site provides immediate access to nitrogen gas whenever needed, eliminating the delays associated with ordering and delivery. This convenience is particularly beneficial in critical applications where downtime is not an option.

Customization & Scalability: Onsite nitrogen generators can be tailored to meet specific flow rate and purity requirements, ensuring optimal performance for diverse applications. Additionally, these systems can be easily scaled up or down to accommodate fluctuating demand, offering flexibility and efficiency.

Environmental Sustainability: Onsite nitrogen generation reduces the carbon footprint associated with transportation and distribution of nitrogen cylinders, contributing to environmental sustainability and corporate social responsibility goals.

Reliability: With onsite nitrogen generation, businesses have greater control over their nitrogen supply, minimizing the risk of disruptions caused by external factors such as supply chain issues or delivery delays.

The use of nitrogen gas for aircraft and automobile tire filling offers significant performance and safety benefits compared to traditional air inflation. The adoption of onsite nitrogen gas generators further enhances efficiency, cost-effectiveness, and convenience, making them a compelling investment for industries prioritizing safety, reliability, and sustainability in their operations. As technology continues to advance, the integration of nitrogen gas solutions is set to play an increasingly pivotal role in optimizing performance across various sectors.

Enquire Now