In the ever-evolving landscape of wastewater treatment, the quest for efficient, sustainable, and cost-effective methods remains paramount. Amidst this pursuit, nanobubble technology has emerged as a promising contender, offering innovative solutions to some of the most pressing challenges in water purification. Central to its efficacy is the utilization of oxygen gas, whose role in enhancing treatment processes cannot be overstated. Furthermore, the adoption of on-site oxygen gas generation represents a paradigm shift in wastewater treatment, providing unparalleled advantages in terms of flexibility, reliability, and environmental impact.

Understanding Nanobubble Technology:

Nanobubbles, as the name suggests, are tiny gas bubbles with diameters typically less than 1000 nanometers. Their minute size grants them unique properties, including prolonged stability and increased surface area, which make them highly effective in various industrial applications, particularly in water treatment. In the context of wastewater remediation, nanobubbles hold immense potential due to their ability to carry and deliver gases such as oxygen deep into the water column, facilitating crucial biochemical processes.

The significance of Oxygen Gas:

Oxygen plays a pivotal role in wastewater treatment by promoting aerobic microbial activity, which is essential for the breakdown of organic pollutants. In conventional treatment systems, oxygen is typically supplied through mechanical aeration methods. However, these approaches often suffer from inefficiencies, including high energy consumption and limited oxygen transfer rates. Herein lies the significance of nanobubble technology, which offers a more efficient means of oxygen delivery, thanks to the enhanced dissolution and prolonged retention of nanobubbles in water. By introducing oxygen in the form of nanobubbles, wastewater treatment facilities can achieve higher oxygen transfer efficiencies, leading to improved pollutant removal rates and overall system performance. Moreover, the small size of nanobubbles allows them to penetrate deep into biofilms and porous media, reaching areas inaccessible to conventional aeration methods, thereby ensuring more thorough and comprehensive treatment.

On-site oxygen gas generation:

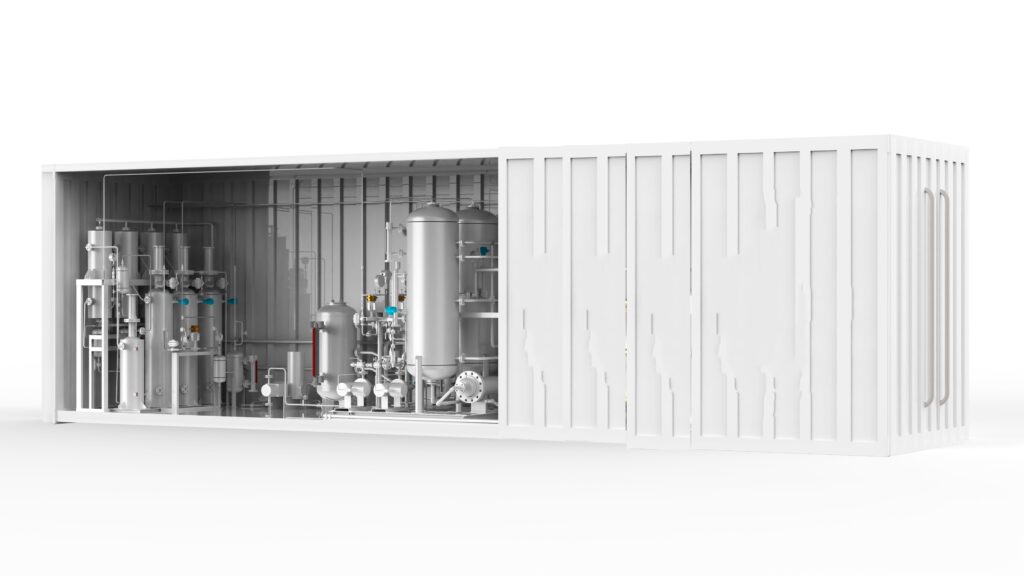

ON-SITE OXYGEN GAS GENERATING SYSTEM

While the benefits of utilizing oxygen gas in wastewater treatment are clear, the logistics of sourcing and transporting large quantities of oxygen present logistical and economic challenges. This is where on-site oxygen gas generation technologies come into play, offering a decentralized approach that minimizes dependence on external suppliers and reduces transportation costs and carbon footprint associated with oxygen delivery.

On-site oxygen generation systems utilize air separation techniques such as pressure swing adsorption (PSA) or vacuum pressure swing adsorption (VPSA) to extract oxygen from atmospheric air. By producing oxygen on-demand at the treatment site, these systems provide greater flexibility and reliability, ensuring a continuous supply of oxygen tailored to the specific needs of the treatment process. Additionally, on-site gas generation eliminates the risks associated with storing and handling compressed oxygen cylinders, enhancing safety and operational efficiency.

SUSTAINABLE APPROACH

In the quest for sustainable and efficient wastewater treatment solutions, nanobubble technology emerges as a transformative innovation, leveraging the unique properties of nanobubbles to enhance oxygen delivery and optimize treatment processes. Central to the success of this approach is the adoption of on-site oxygen generation, which offers unparalleled advantages in terms of reliability, flexibility, and environmental sustainability. As wastewater treatment facilities increasingly embrace the principles of circular economy and resource optimization, the integration of nanobubble technology and on-site oxygen generation is poised to play a pivotal role in shaping the future of water management and environmental stewardship.

Enquire Now