In industrial settings, the need for gases like nitrogen and oxygen is ubiquitous, spanning various applications from manufacturing to healthcare. Traditionally, industrial gas consumers have relied on high-pressure cylinders or bulk liquid tanks to meet their gas requirements. However, the landscape is evolving, with onsite gas generation emerging as a cost-effective and efficient alternative. Let’s explore the pros of onsite nitrogen/oxygen gas generation and the cons of purchasing high-pressure cylinders or bulk liquid tanks, highlighting how industrial gas consumers can save money and achieve a rapid Return on Investment (ROI) within 6-24 months.

onsite gas generation:

STATIONARY ON-SITE GAS SYSTEM

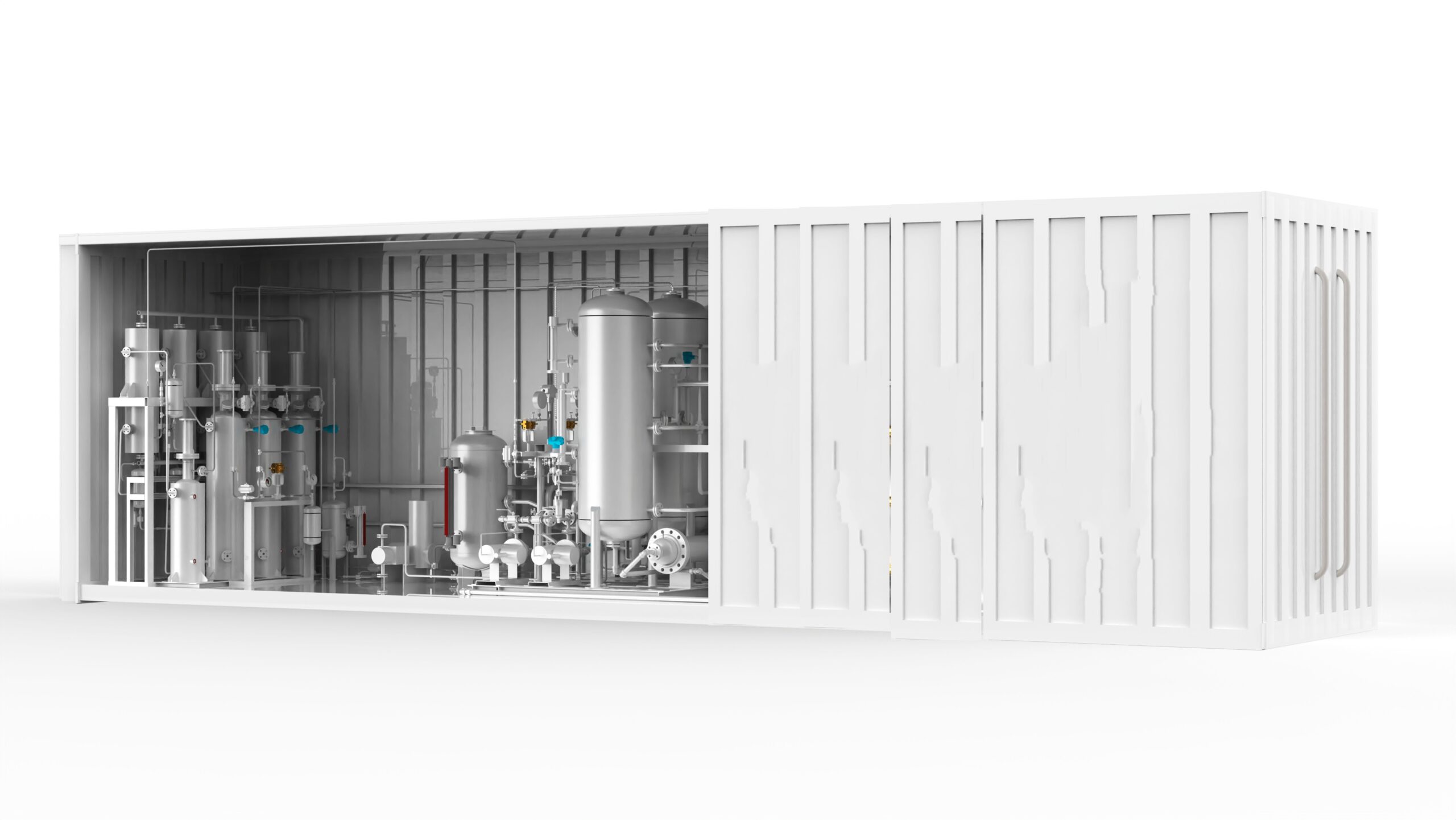

CONTAINERIZED ON-SITE GAS SYSTEM

Cost Efficiency:

Onsite gas generation eliminates the need for repeated purchases of high-pressure cylinders or bulk liquid tanks, which often incur transportation, handling, and rental costs. Once the initial investment in onsite gas generation equipment is made, the cost per unit of gas produced significantly decreases, leading to substantial savings in the long run.

Supply Reliability:

With onsite generation, companies have greater control over their gas supply, reducing the risk of unexpected shortages or disruptions. This reliability translates into improved operational continuity, ensuring uninterrupted production processes and minimizing downtime.

Customization & Scalability:

Onsite gas generation systems can be tailored to specific consumption requirements, allowing companies to produce the exact quantity of gas needed on-demand. Moreover, these systems are highly scalable, enabling businesses to adjust production capacity according to fluctuating demands without relying on external suppliers.

Safety and Environmental Benefits: Onsite generation eliminates the hazards associated with transporting and handling high-pressure cylinders or bulk liquid tanks. Additionally, it reduces the carbon footprint by minimizing the need for frequent deliveries and decreasing reliance on fossil fuel-powered transportation.

Traditional Gas Procurement Methods:

COMPRESSED GAS CYLINDERS

ON-SITE GAS GENERATION SYSTEM

LIQUID BULK TANK

High Operating Cost:

Purchasing gases in high-pressure cylinders or bulk liquid tanks entails recurring expenses, including rental fees, delivery charges, and handling costs. Over time, these expenses can accumulate, significantly impacting the overall operational budget.

Supply Chain Vulnerability:

Reliance on external suppliers for gas procurement exposes companies to supply chain vulnerabilities, such as transportation delays, logistical challenges, and market fluctuations. Any disruption in the supply chain can disrupt operations and lead to costly downtime.

Storage and Handling Challenges:

Storing and handling high-pressure cylinders or bulk liquid tanks require dedicated infrastructure and safety measures, which can consume valuable floor space and resources. Moreover, the handling of these containers poses inherent risks to personnel safety.

Environmental Impact:

Traditional gas procurement methods contribute to environmental pollution through emissions from transportation vehicles and energy-intensive production processes. Additionally, the disposal of empty cylinders or tanks raises concerns regarding waste management and environmental sustainability.

Achieving Cost Savings and Return on Investment:

The transition to onsite gas generation offers a compelling opportunity for industrial gas consumers to optimize their expenditure and realize a rapid ROI within 6-24 months. By investing in modern generation technology, companies can:

- Minimizing Operational Costs: Eliminate recurring expenses associated with traditional procurement methods, leading to significant cost savings over time.

- Enhance Operational Efficiency: Improve supply reliability, reduce downtime, and streamline production processes, thereby maximizing overall operational efficiency.

- Mitigate Risks: Decrease dependency on external suppliers, mitigate supply chain risks, and enhance safety and environmental compliance.

- Future-Proof Investments: Embrace sustainable practices, reduce carbon footprint, and position themselves for long-term growth and competitiveness in a rapidly evolving market.

The advantages of onsite nitrogen/oxygen gas generation are clear: cost efficiency, supply reliability, customization, scalability, safety, and environmental benefits. By contrast, traditional gas procurement methods pose challenges in terms of operating costs, supply chain vulnerability, storage, handling, and environmental impact. Industrial gas consumers can achieve substantial cost savings and a rapid ROI by transitioning to onsite generation, thereby unlocking greater efficiency, reliability, and sustainability in their operations.

Enquire Now